Shepherdstown Cement Mill

The JCHLC maintains the Shepherdstown Cement Mill on the Potomac River. The site includes the ruins of the cement mill and the Battle of Shepherdstown site.

Click on the brochure cover to download.

History of Potomac Mills

In 1826 Shepherdstown physician Henry Boteler and businessman George Reynolds partnered to build a water-powered grist mill called Potomac Mills. The region was a large producer of grain, and the pair was most likely anticipating an increase in trade as a result of the C&O Canal, chartered in 1825. The canal would allow easy shipment of Jefferson County products to the Washington market. Construction on the canal began in Georgetown in 1828. That year Boteler sent a letter to the president of the canal company, Charles Fenton Mercer, informing him of a vast tract of easily quarried limestone on his property that he believed produced excellent natural cement. In September 1828, John Cocke, Jr. was sent to test the limestone in a small kiln and found it was indeed good quality. Because natural, or hydraulic, cement is waterproof and hardens underwater, it was used in large quantities in building the canal. Cement mills sprang up along the Potomac, and Shepherdstown’s was among the largest. Built into a nearby hillside, the first kiln was in operation by April 1829.

The temperature of the large kiln was difficult to control and access was inconvenient so, later that summer, a battery of three smaller kilns was built. It was expanded to a six-kiln battery in 1830 with a small test kiln on one side. The new kilns were closer to the mill, and limestone could be easily loaded into the kilns from River Road. These six kilns could produce up to 1,000 bushels (70,000 pounds) of cement per day, enough to build a canal lock every four days.

Natural cement is made by firing clay-containing limestone to around 1600 degrees, when calcium carbonate becomes calcium oxide (quicklime) and carbon dioxide. Controlling the temperature of a lime kiln is an art. If the kiln is too cool, the reaction cannot take place, but if it is too hot, an inferior “dead burnt” cement is produced. The burned lime is broken by crackers and ground into a fine powder, which then needs only to be combined with water to create the final product. Cement varied greatly from mill to mill according to the mineral content of the limestone. Different limestone layers could even produce vastly different cement from the same quarry. Shepherdstown’s cement in particular was highly regarded. The mill used continuous vertical kilns in which the limestone and fuel were loaded in the kiln throat in alternating layers. The fuel burned away and the limestone was drawn from the bottom to be sent to the mill. The fuel used was usually wood, but the Shepherdstown mill used coal because fewer men were required to maintain the fire, and it was thought to produce a better cement.

Business grew with the canal, but Potomac Mills also ground lime for architectural plaster and fertilizer, while continuing its local function as a grist mill, performing double duty during harvest season. Grinding cement was hard on the stones used for grain so, in July 1829, Boteler and Reynolds contracted an addition to the mill and ordered two new sets of buhr stones from Baltimore. Work was done that summer on the mill dam to make sure there would be sufficient water for their new enterprise. The water ran into a raceway that powered the mill’s wheel, which is no longer at the site but is known to have been 8.6 feet in diameter.

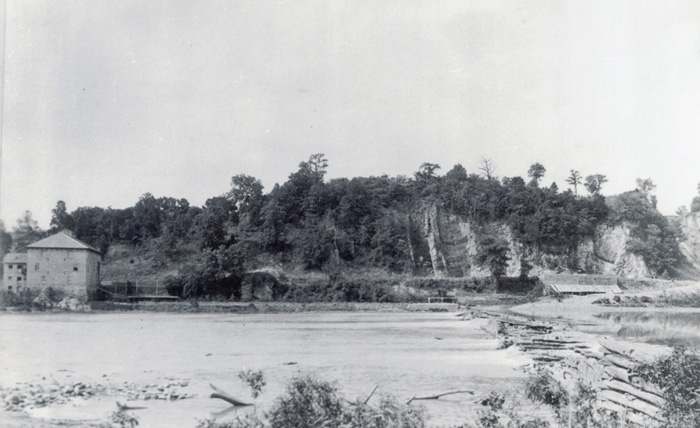

Today the remains of the stone foundation of the dam still create a rapid across the Potomac, but the wood cribbing that was built across the top is completely gone. The remains of the river wall that made up one side of the raceway are mostly intact, and the segmented arches in the mill ruins show the path of the water through the mill complex. At its height, the site employed around 50 men, but business was inconsistent. Production was based on the canal’s changing needs, and the mill was forced to close when the river was too low, flooded, or frozen. In 1829 Boteler and Reynolds built a warehouse on the site to store surplus cement.

In 1834 the C&O canal reached Shepherdstown at Lock 38. An outlet lock was built that year to send both cement and agricultural goods from Jefferson County to the canal using the slack-water pool created by the mill dam. In 1835, Boteler sold his interest in the mill and its adjoining land (nearly 400 acres) to Reynolds. His timing was excellent. In 1837 the Round Top Cement Mill in Hancock, MD opened and became the new chief supplier to the C&O Canal. Without large contracts with the canal, D.C. became the new market for Shepherdstown cement, but business decreased. Reynolds mortgaged everything he owned in 1842. When he defaulted on the mortgage in 1846, the mill went up for auction. It was advertised as containing a grain and plaster mill, several lime kilns, a saw-mill, smokehouse, blacksmith’s shop, several workshops, and a dwelling house. Henry Boteler’s son, Alexander Boteler, purchased the mill complex on 12 acres for $15,000 and continued operations as Potomac Mills, advertising cement and grain products in the Shepherdstown newspaper

through the 1850s.

The Civil War

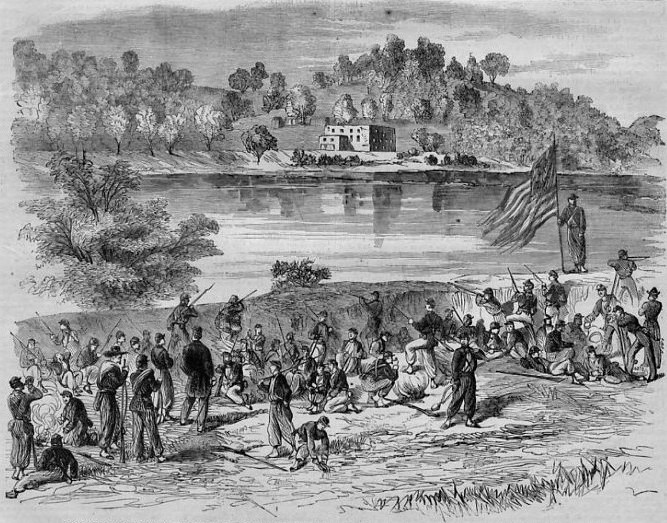

The Potomac River formed a natural barrier between the Union and the Confederacy. Because most of the bridges were burned at the onset of the war, river fords were often the only access into enemy territory and heavily guarded on both sides. The mill’s proximity to Pack Horse Ford put it in a precarious position. The cement mill also offered protection for soldiers firing at their enemy on the Maryland side, and so the 13th Regiment Massachusetts Volunteers burned the mill in August 1861. By this time Alexander Boteler was a colonel in the Confederate Army and a member of the Confederate Congress. His home, Fountain Rock, just outside Shepherdstown, also became a Union target. It was burned in July 1864.

Pack Horse Ford placed the cement mill directly in the war’s path in 1862. Following the Battle of Antietam, General Lee retreated across the Potomac, leaving a rear guard at the ford under the command of William Pendleton. On September 19, 1862, Union forces crossed the river and captured four artillery pieces. On the 20th, Union commander Fitz John Porter dispatched a reconnaissance in force. Fighting ensued around the quarry cliffs and ravines, inflicting enormous casualties and discouraging Union pursuit of Lee’s army. This battle, the bloodiest fought in what is now West Virginia, marked the end of Lee’s Maryland Campaign.

After the War

The Civil War effectively halted business for Boteler, and the mill was sold at auction in 1865. The Potomac Mills Mining and Manufacturing Company, organized in 1867, rebuilt the mill and began milling cement and grain by 1875. Business followed the schedules of the canal and construction in D.C., running from April through December and closing for winter months.

Always subject to the vagaries of nature, and particularly the Potomac, work at the mill halted in times of drought or flood. The flood of 1889, which put the canal out of business until 1896 and flooded the mill complex, dealt a particularly harsh blow. Faced with issues of transporting goods and increasing competition with Portland cement, business ebbed through the 1890s. Potomac Mills closed in 1901 and sat abandoned, vulnerable to destruction from later floods in 1924 and 1936.

During its 75 years of operation, the mill helped supply the plaster and cement that built the C&O canal, regional railroads, and various public buildings in D.C., while serving the local agricultural community. It is the best-preserved of the ten known 19th century cement mills along the Potomac.

Preservation

The cement mill complex is on the south bank of the Potomac River in Jefferson County, West Virginia, approximately one mile east of Shepherdstown on River Road. The site contains the stone foundations of the mill, the kilns, the exterior walls of the warehouse, and the river

wall. The wooden elements of the structures and the 3-story brick walls of the mill are gone, as are the many outbuildings that would have served the site. For your own safety and to protect the remains of an important historic resource, please do not climb on the ruins.

In 2011, with funding from various agencies and grant programs, the Jefferson County Historic Landmarks Commission (JCHLC) purchased the 18-acre site, now under a conservation easement held by the Land Trust for the Eastern Panhandle. When the boundaries of Antietam National Battlefield are amended to include The Battle of Shepherdstown, the JCHLC will pass site ownership to the National Park Service. Potomac Mills was listed on the National Register of Historic Places in 2014. Projects are underway for future visitor services.

For a more detailed history of the cement mill, read “Cement Mills Along the Potomac River” by Thomas F. Hahn and Emory L. Kemp, published by the West Virginia Institute for the History of Technology and Industrial Archaeology in 1994.